Home > Products > Plastic recycling machine > Weast recycling industry: Pyrolysis machine for recycling waste to fuel oil

Weast recycling industry: Pyrolysis machine for recycling waste to fuel oil

- Lianyungang

- T/T Credit Card

You May Like

-

pyrolysis machine in 2014.recycle tire into fuel oil

-

the waste tire recycling production line with pyrolysis technology

-

Crazy Requirement in Pakistan. Waste Tire Recycling Plant from solid tyre to Diesel which can be used for generator directly

-

Big Joint.The Scrab Tyre Pyrolysis Machine with Investment Save

-

the biggest news in 2014: professional pyrolysis equipment supplier move to the new research and manufacture factory

-

No pollution auto pyrolysis plant in china

Product Details

| Place of Origin | Henan, China | Brand Name | sihai | |

| Model Number | LJ-10 |

Product Description

Specifications

1.pyrolysis machine recycle waste to fuel oil2.four by- products process

3.widely used for fuel oil

4.clean process

5.CE

1.Product name

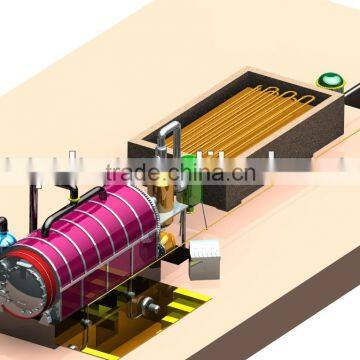

Pyrolysis machine for recycling waste to fuel oil

2.Brief introduction

High efficiency, energy saving, big handling capacity, convenient installation, environment protection … this equipment can make use of waste tyres, plastics, rubbers to refine crude oil, carbon black and steel

Raw materials can be used

Waste/Used rubber tire

Waste industrial mixed plastics,

Waste oil: E.g.: waste diesel oil, engine oil, and other residue oil

Waste cable skin (should first dechlorination treatment)

Waste crude oil and so on.

ing process

First, the raw materials are put into the furnace, then seal the feed inlet then the bottom of the reactor will slowly heat the wastes by coal or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 300-400°C; oil steam will flow through light and heavy components separating device; light component will enter the condenser and meanwhile the residues will be discharged automatically in succession. But the liquefied part will be condensed to rubber oil, and the part that cannot be liquefied will be input into heating supply system for burning by way of combustion gas purification system.

4.Characteristics

1.Environmental protection - The production of the plants is carried out in an environment of no smoking and no smell, the production of the device is environment protective. To refine oil from waste rubber and waste plastics, we turn the rubbish of life into useful oil and carbon black, and help to deal with living organisms, thereby protects the living environment.

2. Safety - the plant has the auto alarm system, when there are some problems, the alarming system will let us know in time, and then we can avoid the accidents.

3. Various handling capacity - we can make the plant to handle different quantity of raw materials according to customers’ requirement, ranging from 7tons to 20tons per 24 hours continuously. We are now researching into the new technology; the new device may be able to deal with 50 tons of raw materials per 24 hours.

4.Energy and manpower saving - the plant can use coal as well as electricity as the fuel, when the temperature reaches to 150°C, a large amount of gases will be generated, these gases can generate a large quantity of heating energy after being burned fully in the special gas boiler, thus can save energy. There will only need two or three persons to control the whole system, it is very convenient.

Treatment of the residues

There are normally 3 kind of residues-exhausted gas, water liquid, waste solid,but all will be processed well down.

1.exhaust gas - By the means of full combustion in water seal and gas burner, the pollution of exhaust gas shall be eliminated and a large amount of fuel shall be saved. Also dust collector will be used to discharge the smoke and dust, and the discharge of the smoke and dust meets the related standards in 2001.

2. waste liquid - Faintly acid waste water will be produced in the process of treatment of oil products, after neutralization by adding faintly alkaline liquor, the neutral waste water shall be harmless to three- grade filtration and can be discharged into special evaporation processor to vapor.

3. Waste solid -

the solid left is carbon black, no solid waste left.

nfiguration of the plants

Plant unit | Name | Specification | Quantity |

Host | Main furnace | 2600*6600 | 1set |

Base of the furnace shell insulation |

| 1set | |

Condensation, Desulfurizati-on & dust removal system | Row-tube condensing system |

| 1set |

Oil – water separator |

| 1set | |

Desulfurization and Dust removal |

| 1set | |

Fan |

| 1 set | |

Reducer | 5.5KW | 2sets | |

Oil – gas exclusion |

| 1set | |

Stream tower |

| 1set | |

Water seal |

| 1set | |

Water pump | 2.2KW | 2set | |

Water pump | 1.5KW | 1set | |

Heavy oil storage tanker |

| 1set | |

| Residue oil tanker |

| 1set |

Damper |

| 1set | |

Chimney |

| 1 set | |

External accessories | Steel, channel steel, gas gun, falanges,blind plates |

| |

Pipe valves, screws, compensator, sealed body | |||

6.The Certificate we got

Contact Us

- Shangqiu Sihai Machinery Equipment Co., Ltd.

- Contact nameHebe Yan Chat Now

- Phone86-370-3163239

- AddressSteel Market, Pingyuan Rd, Shangqiu, Henan, Chia, Shangqiu, Henan

Product Categories

New Products

-

45% tire oil extraction plan pyrolysis tire machine

-

15 days delivery time automatic tyre oil production line

-

Q245R 16 mm steel pyrolysis rubber to oil

-

High quality catalyst for pyrolysis tire to oil

-

Engineers oversea automatic pyrolysis rubber to oil

-

10 tons capacity used tyre pyrolysis system

-

Best quality and lowest price of pyrolysis equipment to recycle waste tire and plastc.

-

The waste tire/rubber/plastic pyrolysis eqiupment with bigger profits margin

-

The waste tire/rubber/plastic pyrolysis eqiupment

-

pyroysis plant about recycle waste tire/plastic to fuel oil

-

Mini Capacity 1-3tons waste tire/rubber pyrolysis machine with long life running

-

Bigger Gear rotary support of pyrolysis machine to recycle waste tire/plastic with long life running

-

Bigger Gear rotary support of pyrolysis plant to recycle waste tire/plastic with long life running

-

New profit industry for waste tyre/plastic pyrolysis plant to recycle waste into oil under professional engineer guideline

-

100 TPD capacity of waste tire recycling machine to fuel oil ,carbon black and steel wire .

-

best value of pryolysis plant for waste tyre with CE /ISO certificate

-

Popular Model !2200mm*6600mm pryolysis plant for waste tyre with CE /ISO certificate

-

Popular Model !2600mm*6600mm pryolysis plant for waste tyre with CE /ISO certificate

-

2014 Highest oil output produce waste tire pyrolysis plant with improved technology and simple carbon black screw discharge

-

2014 Highest oil output produce waste rubber pyrolysis plant with improved technology

-

Completely Automatic Production Line about Recycle Waste tire to oil with ISO & CE certificate.

-

The Scrab Tyre recycling machine to black tyre oil from professional supplier

-

the waste rubber/plastic processing plant to fuel oil

-

waste tire pyrolysis machine to fuel oil with tube pipe in water pool directly cooling system

Popular Searches

- water treatment

- water purifier

- water filter

- water purification

- manganese water filter

- water iron remove

- water tank

- Water Treatment System

- drinking system

- Wastewater Treatment Equipment

- Industrial Equipment

- waste water treatment

- water filter system

- Sewage Treatment Equipment

- Water Treatment Equipment

- electric system

- wastewater treatment

- water plant

- Dewatering Machine

- oil treatment

- Multistage Centrifugal Blower

- water softener

- Chemical Dosing System

- hospital waste

- Waste Water Treatment Equipment

- Water Storage Tank

- uv sterilizer

- water filtration

- reverse osmosis

- ro system

Recommended Products

- High-Performance MBBR Media for IFAS Solutions - Durable PE37 HDPE Biofilm Carrier for Fish Farming

- MBBR Media for Wastewater Treatment Long Service Life MBBR Bio Carrier

- Low Maintenance Cost MBBR K1 Media Bio Filter 25*12mm, Virgin HDPE for Water Landscapes

- MBBR Bio Media Floating Ball for K1K3K5 Wastewater Treatment Plant S Type Mbbr Chipchip for Farm Water Filter Pump Membrane

- MBBR Bio Carrier Waste Water Treatment Bio Media and Bio Ball Water Treatment Machinery Product

- High-Performance Enhanced Biodegradation Porous MBBR Media for Municipal Wastewater Treatment

- MBBR Media for IFAS Solutions Moving Bed Biological Reactors PE37 Hdpe Materiala MBBR Biofilm Carrier for Fish Farming

- High Performance Fish Farm Bio Filter MBBR Media for RAS Fish Farm System

- MBBR Media K1 K3 K5 Media MBBR Biofilm Carriers Advancing RAS Performance Mbbr Technology

- Small Boss Advanced MBBR Biofilter System MBBR Filter Media Mbbr Carrier Media K5 Filters for RAS Fish Farming

- Manufacturer RAS Fish Farm Waste Water Treatment K1 K2 K3 K5 MBBR Media Moving Bed Filter Media

- Fish Farming MBBR Bio Media Carriers Biofilter K1 K3 K5 Virgin PE Biofilm Reactor for RAS Aquaculture

Find Similar Products By Category

- Industrial Equipment & Components > Environment Protection Device > Waste Treatment Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Hebe Yan

Hi there! Welcome to my shop. Let me know if you have any questions.

Hebe Yan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile

We will contact you as soon as possible�Q?/p> Continue View